Creating custom glasses is a meticulous process that blends creativity, precision, and technical expertise. We structure the process into clear and concise steps, ensuring that you have a seamless experience from concept to delivery.

Whether you’re deeply familiar with eyewear or just starting your journey, our step-by-step customization process guarantees you’ll end up with a pair of custom glasses that are uniquely yours.

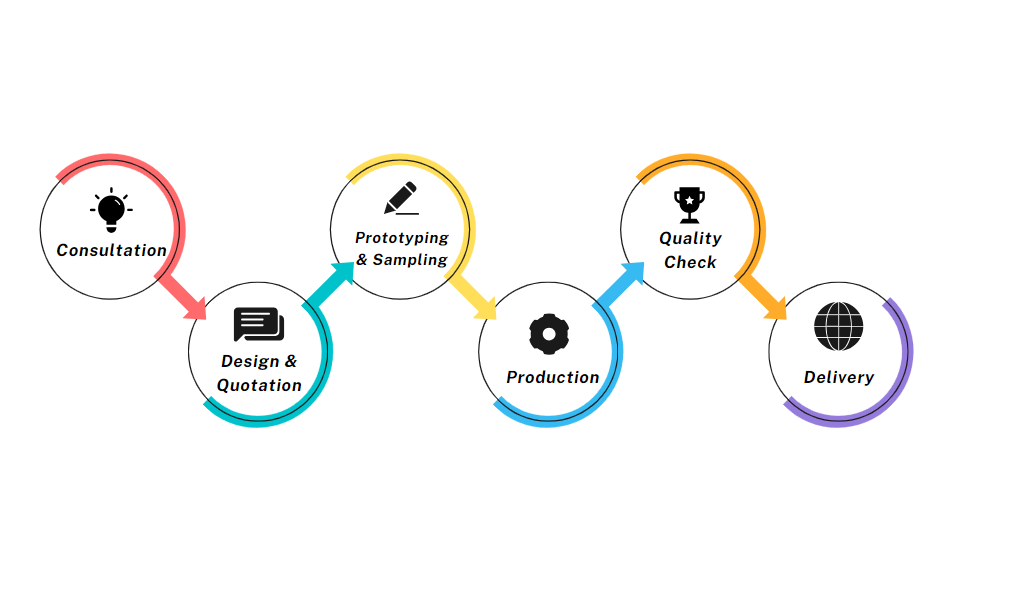

The Custom Glasses Creation Process

Consultation

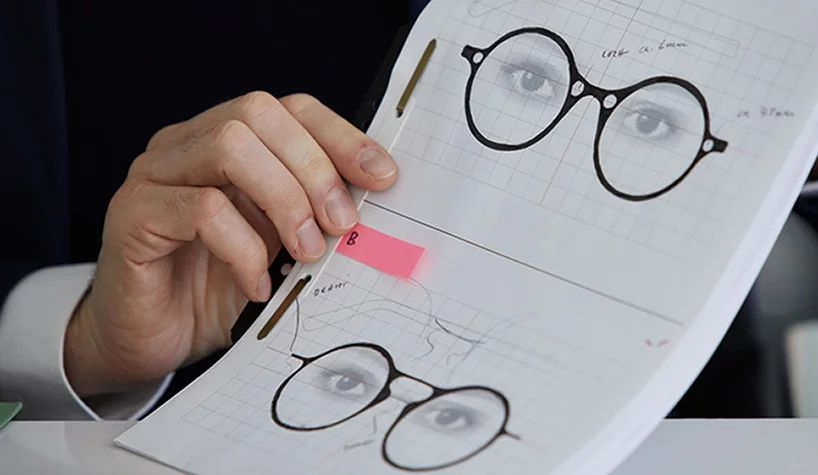

The first step in the custom glasses customization process involves an in-depth consultation. Tell us what kind of custom glasses you want, or show us your sketches.

During this phase, we discuss your design preferences, including specifics like size, shape, materials, and color options.

This conversation lays the foundation for custom glasses, ensuring that the final product aligns perfectly with your vision and needs.

Design & Quotation

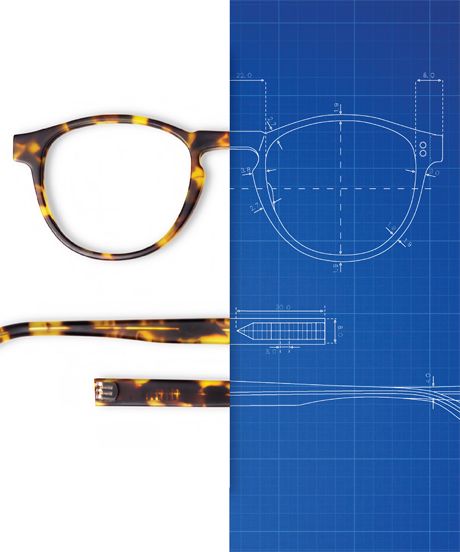

Once we have finalized the design concept, our team will begin creating detailed design drawings. These drawings incorporate all the elements discussed during the consultation, such as size range, frame shape, and color.

We will conduct an engineering assessment to ensure the feasibility of the design, followed by the creation of precise engineering drawings. CAD drawings will be provided for you to confirm all details.

After all the details are confirmed to be accurate, we will provide a quote to you.

Prototyping & Sampling

With the design finalized, we move on to the prototyping phase. Here, a physical prototype of eyewear is produced. This prototype serves as a tangible representation of the design, allowing you to assess the look and feel of the glasses before full-scale production begins.

After the prototype is approved, we create various samples, including color samples, photo samples, and pre-production samples. These samples allow you to see the actual colors and materials in use.

Usually the sample production takes 30-45 days, depending on the complexity of the product.

Mass Production

Once the samples receive final approval, we move forward with full-scale production, ensuring every detail meets the agreed-upon specifications. Depending on the material selected—such as acetate, titanium, or TR90—the production process can vary significantly.

Metal Frames: Common materials include copper, zinc, nickel, titanium, and aluminum.

Acetate Frames: These frames derive their colors primarily from the acetate material itself. For additional creativity, acetate lamination can be used.

Injection Frames: Injection frames involve a longer production time due to the expensive molds required.

The typical production cycle takes 70-90 days.

Quality Check

Quality is paramount in the custom glasses industry. Before the products are shipped, we perform thorough inspections to ensure that every pair of custom glasses meets our high standards. This includes testing the frames for durability and conducting a sampling inspection to catch any potential defects.

Delivery

The final step in the process is delivery, where your custom glasses reach their ultimate destination. Once the glasses have successfully passed all quality checks, including durability and visual inspection, they are carefully packaged to ensure maximum protection during transit.

We use secure, eco-friendly packaging materials to prevent any potential damage and preserve the integrity of your glasses. Whether shipping domestically or internationally, we ensure a reliable delivery experience, so your custom glasses arrive in pristine condition, ready to wear.

Conclusion

From the initial consultation to the final delivery, each phase is carefully managed to produce high-quality, bespoke eyewear that perfectly matches your vision. Whether you’re looking for a specific design, material, or fit, this process guarantees that your custom glasses will not only look great but also feel comfortable and perform reliably.

By following this structured approach, we ensure that every customer receives a product that is both unique and of the highest quality, tailored specifically to their needs.