In the world of eyewear design, the glasses logo is a critical element that not only identifies the brand but also adds a distinctive touch to each logo frame. Various techniques are employed to achieve logo printing on eyewear, each offering different advantages and limitations. Let’s explore the characteristics of these glasses logo processes.

Logo Printing – Pressing

Pressing is a popular technique for imprinting the sunglasses logo on frames. This process involves pressing a mold into the material under high pressure, imprinting the logo onto the surface.

- Advantages:

- High Metal Purity: The pressing process ensures that the metal used for the glasses logo or sunglasses logo maintains a high degree of purity, enhancing the overall quality of the frame.

- Diverse Material Options: Pressing can be applied to various materials, making it versatile for different eyewear designs.

- Durable and Hard Logos: The logos created through pressing are dense and hard, providing excellent durability.

- Ease of Polishing: The Pressed logos can be easily polished to achieve a smooth and shiny finish, adding to the premium feel of the eyewear.

- Limitations:

- Edge Detail: The process may not achieve highly detailed edges, which might result in less refined logos.

- Design Constraints: Pressing typically allows for patterns only on the top and bottom surfaces, limiting design flexibility.

- Fragility in Fine Details: Very intricate or small designs may not be feasible due to the risk of mold breakage during the stamping process.

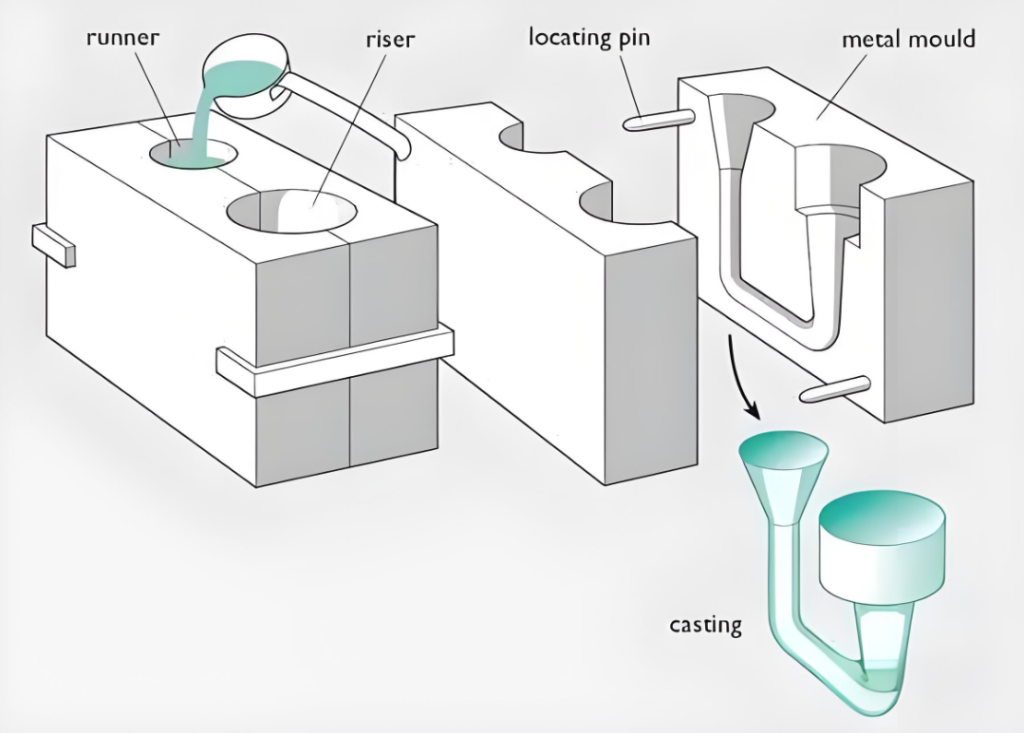

Logo Printing – Casting

Casting is a process where liquid metal or plastic is poured into a mold, which hardens to form the glasses logo. This technique is ideal for creating complex logo frames that need to extend across multiple surfaces of the frame.

- Advantages:

- Complex Designs: Casting enables logo printing with patterns on all sides of the frame, offering greater flexibility.

- Versatility: This method supports intricate and three-dimensional glasses logo designs that pressing cannot achieve.

- Limitations:

- Production Time: The mold creation process for casting can take up to 15 days, which may slow down production.

- Color Brightness: Material constraints may prevent casting from achieving vibrant colors, limiting its use for colorful logo printing.

Logo Printing – BMT

BMT refers to a type of metallic sticker used for glasses logos. When applied to the logo frame, it protrudes only 0.1-0.15mm, creating a seamless feel that integrates smoothly with the frame while maintaining a metallic sheen and an upscale appearance.

- Advantages:

- Seamless Integration: The minimal protrusion makes the BMT glasses logo feel like part of the logo frame, offering a smooth and cohesive appearance.

- Premium Appearance: The metallic finish adds a luxurious touch, elevating the overall aesthetic of the logo frame.

- Limitations:

- Higher Costs: Precision and craftsmanship in creating the BMT glasses logo can make it relatively costly.

Logo Printing – UPT

UPT is a type of segmented metal label made from materials like nickel, chromium, or copper. It is known for its strong three-dimensional effect. UPT stickers can be produced through various processes, including electroforming, etching, and screen printing, making them a versatile alternative to traditional adhesive labels and metal plates like aluminum, copper, and iron.

- Advantages:

- Three-Dimensional Effect: The design and material of UPT logos provide a noticeable depth, adding visual appeal to glasses logos.

- Versatility in Production: UPT allows for logo printing through multiple processes, providing flexibility in design and application.

- Limitations:

- Edge Precision: The edges of UPT stickers may not be as smooth and refined as other methods.

- Potential Lifting: If the sticker is too thick, there is a risk that the edges may lift or peel over time.

Logo Printing – Epoxy Resin

The epoxy resin process is used for logo printing on acetate logo frames. This involves engraving a groove, inserting a metal glasses logo, and covering it with clear epoxy resin.

- Advantages:

- Aesthetic Appeal: Epoxy resin seamlessly integrates the metal logo with the acetate frame, providing a sleek and high-end look for the logo frame.

- Enhanced Durability: The resin layer protects the logo printing from wear, oxidation, and environmental factors, ensuring the logo maintains its appearance over time.

- Limitations:

- Layering Visibility: The transparency of the epoxy resin can cause noticeable layering, especially if there is a strong color contrast between the frame and the glasses logo.

- Surface Texture: The resin may not completely smooth the surface, making the logo frame detectable by touch.

- Complex Production: This multi-step process requires time and precision, which can increase production costs for logo printing

Logo Printing – Laser Engraving

Laser engraving employs a focused laser beam to etch glasses logos onto the surface of the eyewear frame.

- Advantages:

- High Precision: Laser engraving provides exceptional detail and accuracy, making it perfect for finely detailed glasses logos and sunglasses logos.

- Long-Lasting Durability: The engraved logos are permanent and highly resistant to wear, ensuring the logo frame retains its look over time.

- Material Versatility: This logo printing technique is suitable for a wide range of materials, including metal, plastic, and wood.

- Limitations:

- Limited Longevity for Extended Use: Laser engraving is not ideal for creating highly complex or detailed patterns over large surfaces, as it’s not suited for prolonged usage on intricate designs.

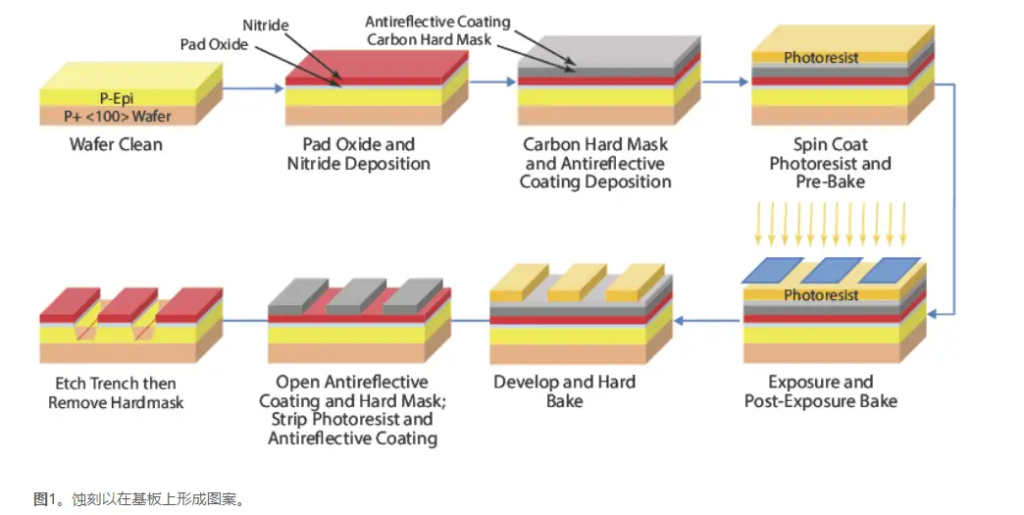

Logo Printing – Etching

Etching is a chemical process used to remove material from the frame surface, creating a glasses logo.

- Advantages:

- Production Speed: Etching is a fast process, making it ideal for quicker production runs of glasses logos and logo frames.

- Elegant, Subtle Finish: This method creates a recessed logo frame with a subtle and refined appearance that is durable and resistant to wear.

- Limitations:

- Stability: Etching may not be stable enough for all designs, particularly those requiring precise right angles.

- Detailing: It cannot produce very sharp or precise angles, which might limit the complexity of the design.

Logo Printing – CNC Engraving

CNC engraving is a process that uses automated machine tools with a program control system to precisely carve glasses logos onto the frame. This system processes control codes or other symbolic instructions to guide the tool’s movement, allowing for highly accurate and controlled logo printing.

- Advantages:

- High Precision: CNC engraving ensures very controlled and accurate carving of glasses logos, achieving consistent and reliable results.

- Customizable: Perfect for creating custom logo frames with stable and repeatable outcomes.

- Limitations:

- Design Complexity: Typically limited to simpler patterns; not suitable for highly detailed or very small logo designs.

- Production Speed: Slower than other logo printing methods, which may affect production timelines for large orders.

Logo Printing – Silk-Screen

Silk-screen printing is a traditional method in which ink is pressed through a mesh screen onto the logo frame, creating the glasses logo. This technique supports multi-color logo printing and can be applied to both flat and curved surfaces.

- Advantages:

- Multi-Color Capability: Enables vibrant, multi-color logo printing, ideal for creating visually striking glasses logos.

- Cost-Effective for Large Runs: Economical for high-volume production, reducing per-unit costs.

- Limitations:

- Durability: Printed logos may not last as long as engraved or stamped glasses logos.

Logo Printing – Pad Printing

Pad printing uses a silicone pad to transfer ink onto the logo frame, ideal for curved or irregular surfaces.

- Advantages:

- Versatility: Ideal for logo printing on complex shapes and curved logo frames, accommodating diverse design needs.

- Fine Detail: Capable of achieving detailed, intricate designs, making it suitable for precision glasses logos.

- Limitations:

- Durability: Similar to silk-screen printing, pad-printed logos may not be as long-lasting as logos created through other methods like engraving or stamping.

Conclusion

Selecting the appropriate logo printing technique depends on factors such as the eyewear frame material, logo design complexity, production timeline, and desired aesthetic. Each method brings distinct benefits, whether it’s the high purity and durability of stamped logos, the intricate possibilities of casting, the efficiency of etching, or the precision offered by CNC engraving.

Understanding the advantages and limitations of each logo printing technique allows you to make informed choices that align with your brand’s identity, ensuring that your glasses logo or sunglasses logo leaves a lasting impression.